Heating systems:

The most intensive production in greenhouses and glasshouses occurs during the cold season, when temperatures can be very low. A drop in temperature below the minimum optimum within the protected environment can cause various physiological disorders in cultivated plants, such as halted vegetative growth, fruit deformation, and similar issues. Additionally, frost with extremely low temperatures over extended periods can result in total crop and harvest loss, significantly impacting yields.

At META-PLAST d.o.o., we have many years of experience in installing and maintaining heating systems that provide your crops with ideal temperatures for growth and development. Our solutions are tailored to the specific characteristics of your greenhouse or glasshouse, taking into account geographical location, type of available fuel, and other important factors.

Our technical department, after thorough analysis and study, can provide you with the best solution for installing a heating system with optimal capacity and key components that ensure proper and efficient operation. Our solutions not only protect your crops from the harmful effects of low temperatures but also enable continuous and successful production throughout the year.

Central heating system (hot water)

Central heating systems are recommended for locations with low minimum outdoor temperatures, where large temperature differences between the interior and exterior are required. These systems are ideal for crops that need high minimum temperatures for optimal growth and for projects aiming for high productivity and a high level of automation.

In many cases, central heating systems are integrated as part of the overall greenhouse or glasshouse system, serving, for example, as heating pipes that also function as tracks for work trolleys, harvesting carts, or spraying equipment. Additionally, heating systems are often used as a tool for regulating humidity in the fruit zone, reducing the risk of disease.

AIR HEATING

Heating systems:

The most intensive greenhouse crops often go through their cycles during the cold season, when a drop in temperature below the optimal minimum can cause various physiological disorders, such as halted vegetative growth and other issues. Frost, especially at extremely low temperatures lasting for an extended period, can result in total crop failure and harvest loss.

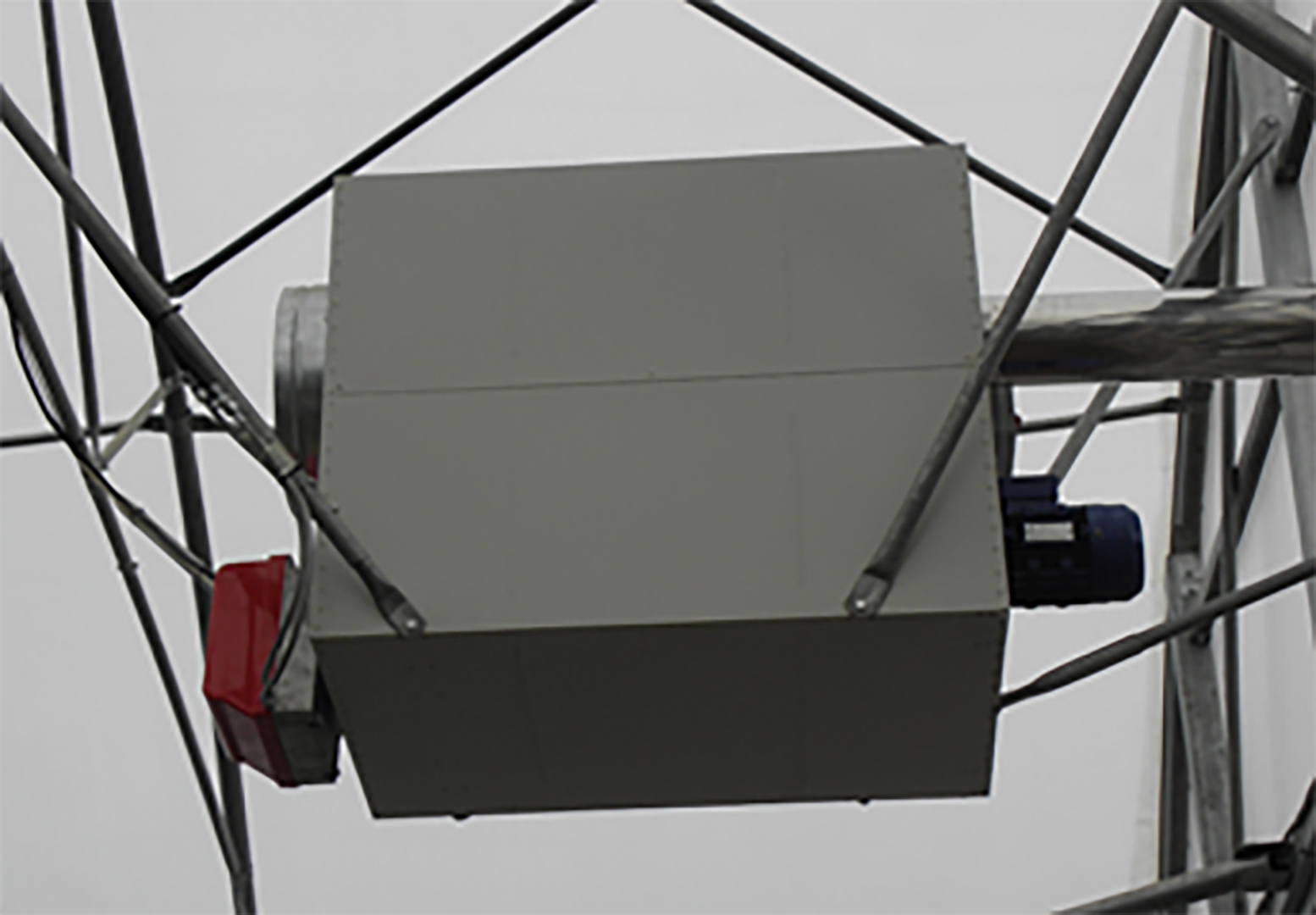

Hot air generator heating system:

Hot air generator heating systems are recommended for locations with mild minimum outdoor temperatures, where crops require an optimal minimum temperature that is not very high. These systems are ideal for projects aiming to increase the speed and productivity of cultivation during cold periods. They also serve as an adequate solution for projects where the equipment is primarily needed as a safety measure against frost.

The operation of a hot air generator is based on producing heat from a specific fuel in the combustion chamber, which is an integral part of the air-to-air heat exchanger.

Fuel is burned in the combustion chamber using either an atmospheric or pressurized burner, depending on the model. The heat is then transferred to the air in the greenhouse via the secondary side of the heat exchanger, with an axial fan ensuring efficient distribution of the heated air. The appropriate number and arrangement of generators, combined with optimal airflow speed and fan range, allow for even distribution of hot air throughout the entire greenhouse volume, ensuring ideal conditions for plant growth.